MPCS 2

Tundish spraying machine

Description

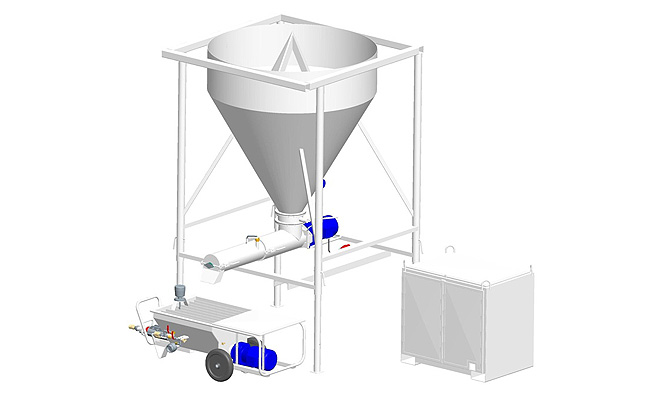

The MPCS 2 metallurgical lining and concreting machine is a professional assembly for production, conveyance and application of refractory magnesite spray liners and production of refractory concretes. The machine comprises a large, 4.0m3hopper, a refractory mortar pump and a control unit which is located in a robust cabinet incorporating a water tank with an integrated pump and heating.

Operation

1. Preparation, conveyance and application of refractory mortars onto steelmaking intermediate ladles:

The mixture is supplied in big bags and it is filled into the hopper with a bag-tearing device by means of a crane. The mixture then falls from the hopper into the continual mixer. The mixture is mixed with water in the continual mixer and then it falls into the pump funnel. Then the mixture is further agitated in the funnel and fed to the screw pump. The pump presses the finished mortar into conveyance hoses that feed the mortar to the liner sprayer. The mortar is then applied onto the ladle wall by means of compressed air.

2. Preparation and application of refractory concrete mixtures:

The mixture is supplied in big bags and it is filled into the hopper with a bag-tearing device by means of a crane. The mixture falls from the hopper into the continual mixer where it is mixed with water, and then it falls directly onto the place being concreted.

Parametry

| Technical specification | Dimensions | ||

| Hopper capacity | 4 m3 | Lenght | 3700 mm |

| Performance | 40 l/min. | Width | 2700 mm |

| Delivery distance | Height with hopper | 3560 mm | |

| -horizontally | 40 m | ||

| -vertially | 25 m | Weight | 830 kg |

Accessories

| Gun | 1 pcs |

| Conveying hose DN 25-15m | 1 pcs |

| Air hose 15 m | 1 pcs |

| Remote control | 1 pcs |

| Water hose | 1 pcs |

| Air hose | 1 pcs |

| Cleaning hose | 1 pcs |

| Power cable | 1 pcs |

| Test manometer | 1 pcs |

| Stator D5 | 3 pcs |

| Rotor D5 | 3 pcs |

| Seal MDR 25 | 6 pcs |

| Cleaning tool 25 | 5 pcs |

| Greasing tool | 1pcs |

| Key 24x27 | 1 pcs |

| Metal nozzle | 5 pcs |